1. Cov ntsiab lus ntawm kev teeb tsa

Txoj hauj lwm ntawm kev teeb tsa ntawm lub kiv cua

Cov ntawv ceeb toom ntawm kev xaiv txoj haujlwm raws li hauv qab no:

Yog tias tus kiv cua hauv qhov qhib cua, nws yuav tsum muaj kev tiv thaiv.

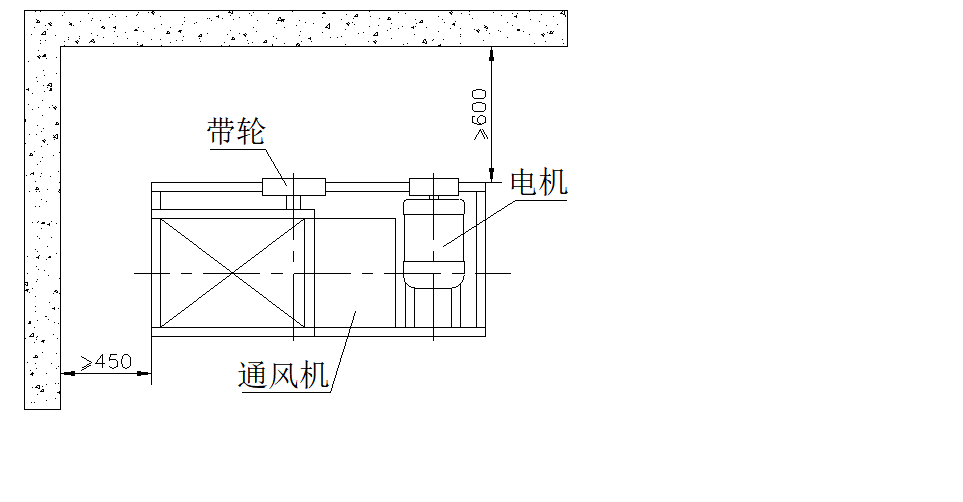

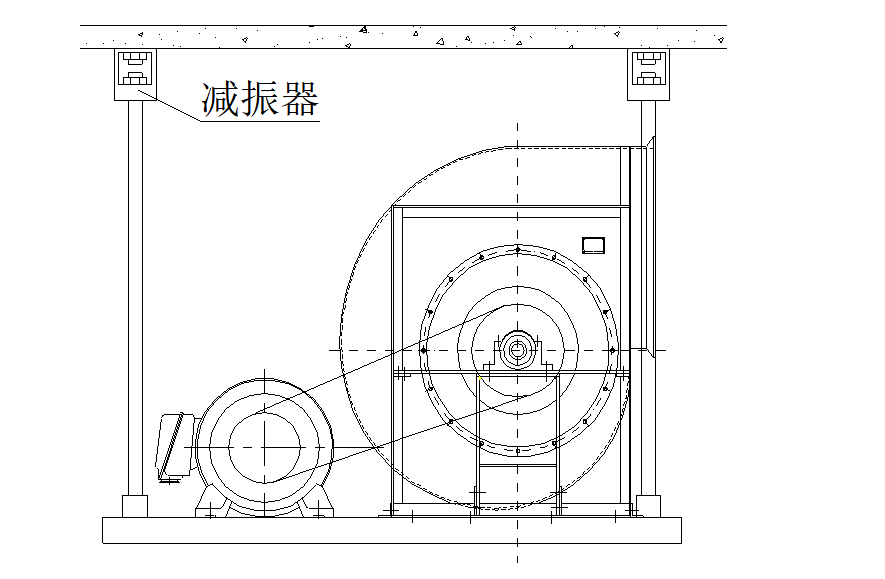

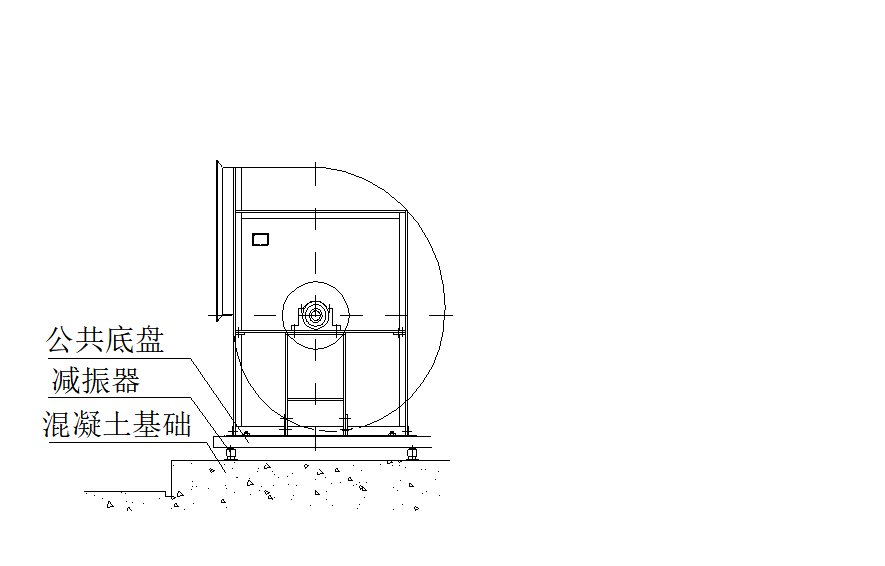

Lub kiv cua yuav tsum tau nruab rau hauv qhov chaw uas yooj yim rau kev tswj thiab saib. Saib daim duab 1.

Daim duab 1

Qhov chaw yuav tsum muaj qhov yooj yim.

Tshwj xeeb tshaj yog cov kiv cua yuav raug ntsia rau ntawm cov nyiaj siv ua haujlwm, qhov chaw tsis muaj qhov cuam tshuam ntawm kev co yuav tsum.

2. Kev thov ntawm qhov chaw

Koj yuav tsum tau them sai sai rau kwv yees qhov acreage ntawm installation raws li hauv qab no:

Tsis txhob cuam tshuam lwm lub tshuab ncig nws.

Tshawb xyuas thiab kho yooj yim.

Muaj qhov chaw txaus rau tshem tawm impeller.

3.Txoj kev thiab kev xav tau ntawm kev teeb tsa

1.Ua rau hauv av.

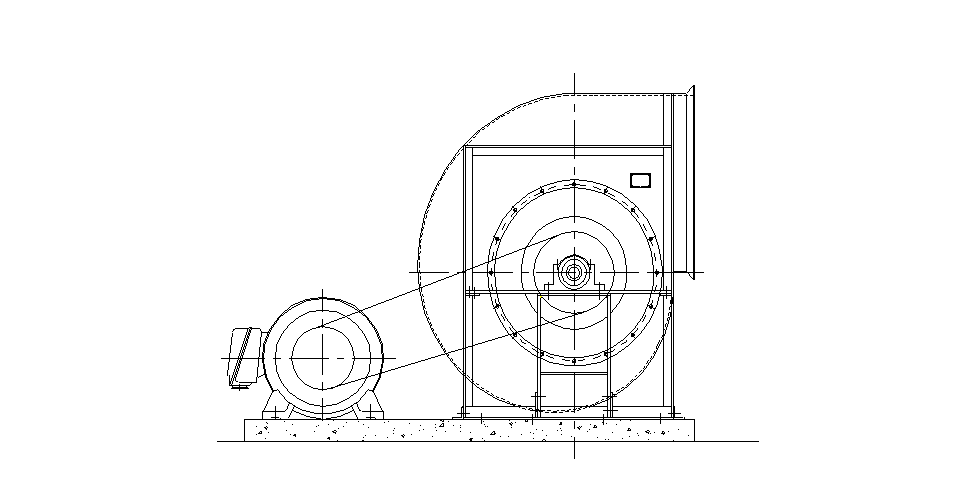

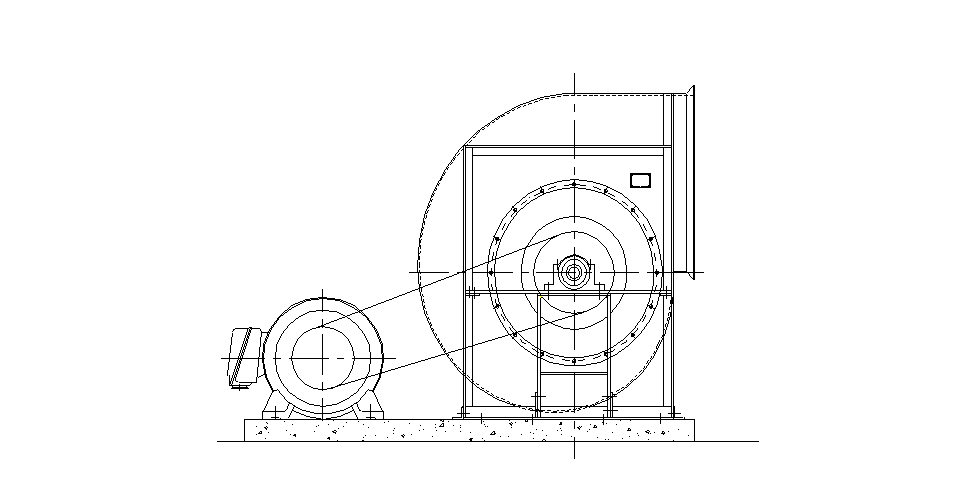

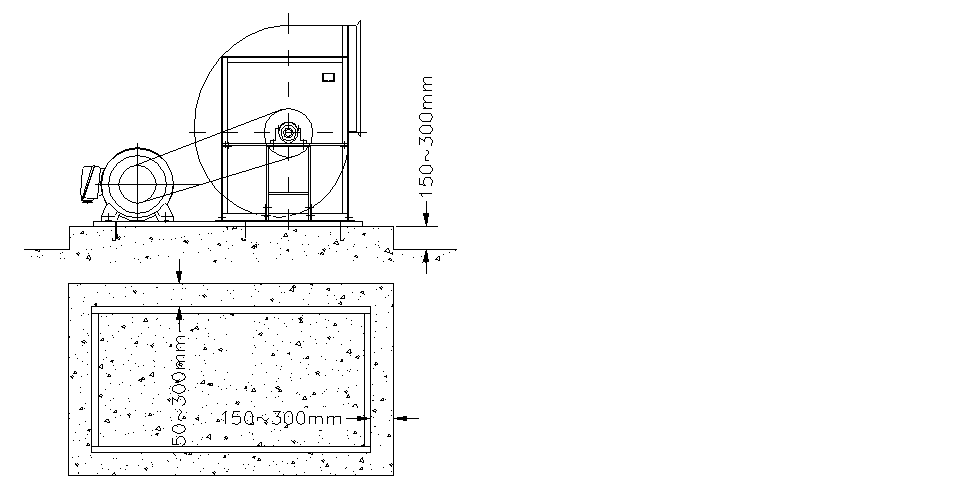

Cov kiv cua feem ntau yog ntsia rau ntawm cov pob zeb ua vaj tse tshwj tsis yog cov kiv cua me me nrog hom me thiab lub cev muaj zog. Txawm li ntawd los, koj yuav tsum tau them sai sai rau qhov siv ntawm qhov yooj yim. Saib daim duab 2.

Daim duab 2

2.Nyob rau hauv lub hahpace.

Koj yuav tsum tau them sai sai rau lub angular rigidity thiab kev siv ntawm lub installation cheeb tsam kom tsis txhob resonance, txwv tsis pub txais kev ntsuas ntawm reinforce. Saib daim duab 3A.

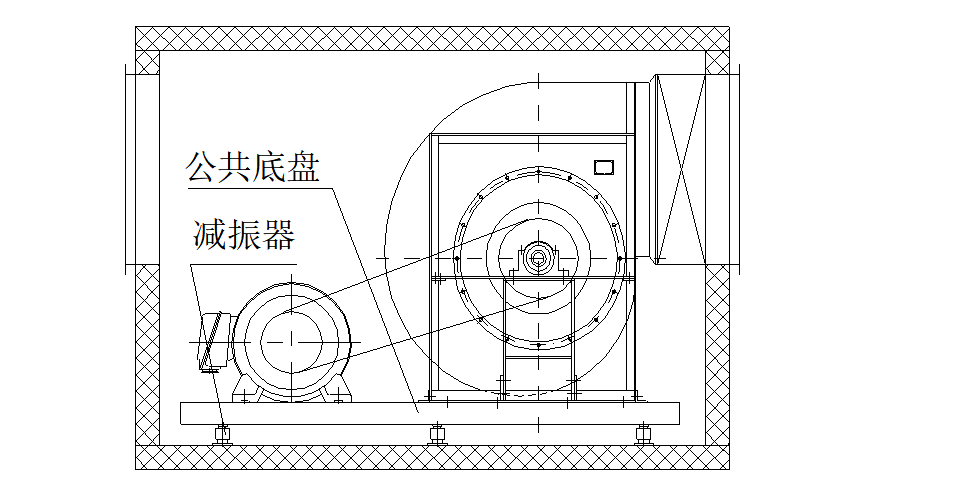

3.Ua rau hauv lub thawv ntxuam.

Yuav kom tsis txhob muaj libration uas yuav tshwm sim los ntawm tsis muaj rigidity thiab siv ntawm lub thav duab, koj yuav tsum tau xyuam xim rau qhov siv. Tshwj xeeb tshaj yog thaum siv roj hmab los yog caij nplooj ntoos hlav vibration damper, kiv cua thiab lub cev muaj zog yuav raug ntsia rau tib lub underpan. Saib daim duab 3B.

Daim duab 3A

Daim duab 3B

Daim duab 4A

Daim duab 4B

4.Ua dai saum lub qab nthab

Cov kiv cua me me yuav tsum tau nruab nrog bolts yooj yim, (Saib daim duab 4A). Cov kiv cua nruab nrab yuav tsum tau nruab nrog cov vuam ntawm cov ncej, tab sis tom qab ntawd muab ntsia rau hauv av kom zoo tshaj plaws ntawm koj lub peev xwm.

Thaum tso cov kiv cua yuav tsum tau nruab rau ntawm phab ntsa, phab ntsa yuav tsum ceev ceev.

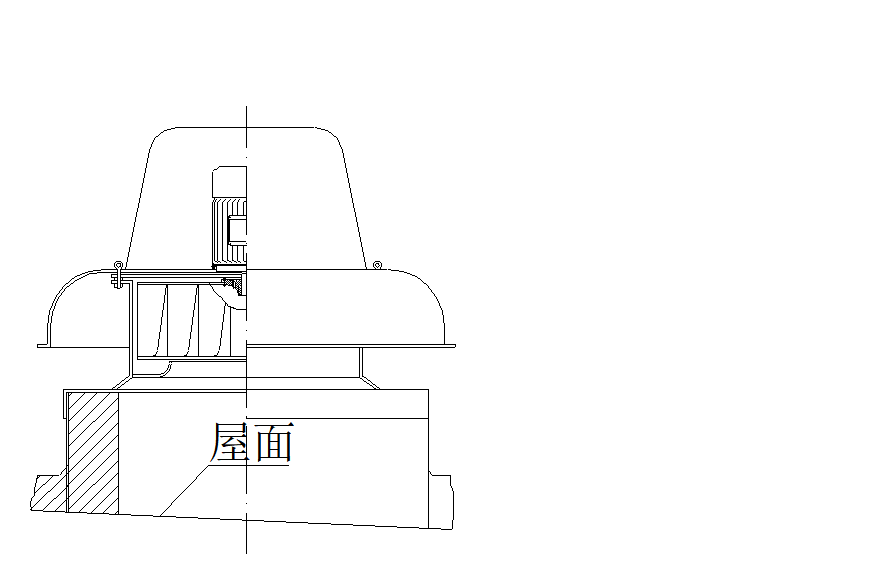

Muab ntsia rau ntawm lub ru tsev.

Koj yuav tsum xav txog qhov cuam tshuam los ntawm cua daj cua dub, nag thiab daus. Saib daim duab 4B.

2.Basic

1. Qhob pem teb

Lub dav hlau loj ntawm cov pob zeb ua vaj tse loj dua 150 ~ 300mm tshaj qhov loj ntawm kiv cua ciam teb. Qhov ntau thiab tsawg ntawm cov pob zeb pob zeb rau cov kiv cua me me yog qhov tsawg kawg nkaus tab sis nws cov tuab yog loj dua 150 hli yuav tsum thiab qhov hnyav yog qhov loj dua 5 ~ 10 ntau dua qhov hnyav ntawm tag nrho cov kiv cua. Saib daim duab 5

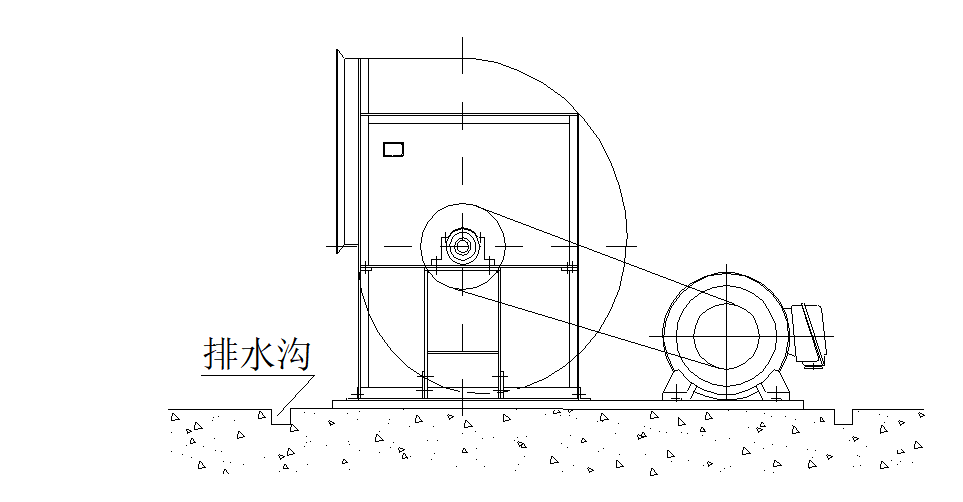

Koj yuav tsum mount ib tug ntws rau tsis muaj dej nyob rau hauv lub hauv paus, thiab hais tias nws yuav tsis eroded. Saib daim duab 6.

Qhov saum npoo ntawm qhov yooj yim yog du thiab luas, koj yuav tsum xav txog lub qhov rau kev txhim kho lub bolts ua ntej.

Daim duab 5

Daim duab 6

Tswj lub hauv paus nto thiab kiv cua ncej nrog gasket, ces kho tom qab qhov yooj yim tuaj rau hauv kev sib cuag nrog lub gasket txaus.

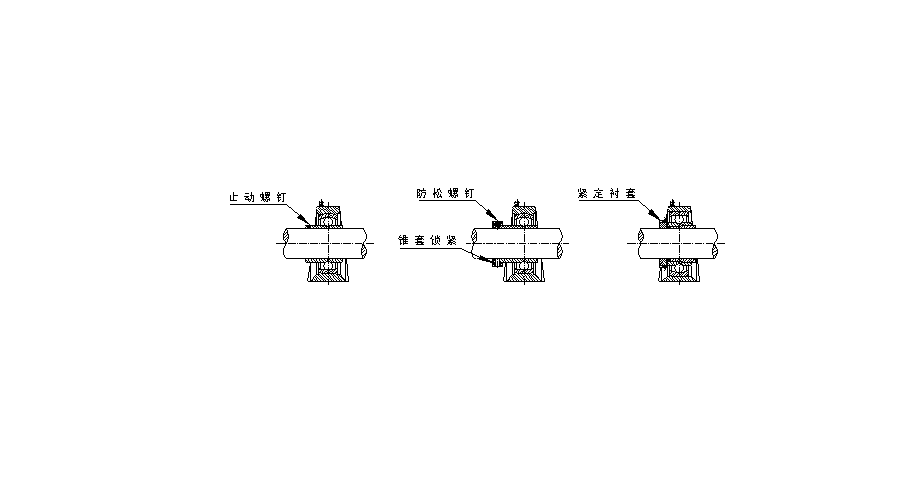

2.Shakeproof keeb

Shakeproof ntsiab muaj xws li gaskets, roj hmab, caij nplooj ntoos hlav thiab lwm yam. Saib daim duab 7.

Koj yuav zoo dua xaiv qhov tseeb shakeproof ntsiab raws li qhov hnyav thiab kev ua haujlwm zaus ntawm tus kiv cua. Yog tias tus kiv cua khiav qis qis lossis thauj khoom me me, cov khoom shakeproof tuaj yeem xaiv cov roj hmab.

Daim duab 7

3.Siv cov khoom shakeproof

Lub underpan qhov twg tau nruab kiv cua thiab lub cev muaj zog muaj qhov txaus angular rigidity thaum koj siv cov khoom shakeproof.

Qhov yooj yim yog aclinic rau lub hom phiaj ntawm tag nrho cov shakeproof ntsiab txhawb sib npaug. Yog hais tias muaj dab tsi nyob rau hauv tus ncej, tus kiv cua yuav shaken unconventionally.

Thaum siv lub shakeproof caij, koj yuav tsum nruab hloov tau yooj yim khi-nyob rau hauv cov yeeb nkab sib txuas ntawm tus kiv cua.

Qhov sib npaug ntawm impeller yuav raug rhuav tshem thaum plua plav lossis eyewinker cling rau lub impeller, qhov no, siv cov khoom shakeproof tsis raug.

3.Kev thauj mus los, tso nyiaj, kev nyab xeeb

Txhua tus kiv cua tau kuaj xyuas nrog qhov nruab nrab emendation, sib npaug, khiav, tom qab ntawd tsim nyog tawm ntawm lub Hoobkas, yog li tus neeg siv yuav tsum tau them sai sai rau qhov abrade thiab distortion thaum caij tsheb thauj mus los.

1. Tshawb xyuas qhov chaw

Tshawb xyuas cov kiv cua seb puas muaj kev puas tsuaj, kev tsis sib haum xeeb, cov xim tsis zoo.

Xyuas cov khoom thiab cov khoom seem.

2.Hoist thiab kev thauj mus los

Thov siv tus nuv thaum hla, perching thiab hoisting.

Thaum hoisting fission casing thiab rotors, sau nyob rau hauv nrog mos qhov twg lub rigging thiab workpiece kov, tshwj xeeb tshaj yog lub impeller thiab ncej. Txwv tsis pub yuav debase qhov precision ntawm qhov sib npaug, ua rau cov kiv cua shaken.

Ua tib zoo saib xyuas cov rigging rau lub pulley thiab tooj dag lubrication txiv mis yog qhov yooj yim.

Kev txav ntawm cov cuab yeej nqa loj impulsive quab yuam ntawm ncej, rub thiab impeller, thov tshaj tawm nws.

Kev txav ntawm cov cuab yeej nqa loj impulsive quab yuam ntawm ncej, rub thiab impeller, thov tshaj tawm nws.

Thaum lub sijhawm khaws cia, hais kom ob zaug jigger ib hlis tsawg kawg, 10 tig txhua zaus thiab nres ntawm qhov taw tes ntawm 180 °. Nyob rau tib lub sij hawm, xyuam xim rau lub degree ntawm bearing lubrication. Thib ob, qee lub sij hawm qhib thiab kaw lub rotor xws li lub qhov rooj kho tau, yog tias tsim nyog, immit lub lubrication txhawm rau tiv thaiv xeb.

Txhawm rau kuaj xyuas cov libricate tom qab qhib lub hau npog yog tias tus kiv cua tsis tau khiav ntev, ntxiv lub roj tshiab yog tias tsim nyog.

4.Txoj kev ntawm kev teeb tsa

Txawm hais tias tus kiv cua thiab lub cev muaj zog tau ua pov thawj ua ntej tawm hauv lub Hoobkas, koj yuav tsum rov nyeem dua tom qab lub kiv cua yuav nruab rau ntawm lub hauv paus vim kev thauj mus los thiab hloov pauv hloov pauv ntawm lub hauv paus ib se.

1. Kev tsim kho

Nyob rau hauv txoj cai, lub dav hlau kiv cua yuav siv sij hawm benchmark nrog ncej, tab sis thaum lub axile kiv cua yuav raug ntsia los ntawm sawv hom, lub dav hlau kuj yuav siv sij hawm benchmark nrog cover ntawm V-siv los yog impeller hub.

Xyuas lub dav hlau nrog gradienter tom qab nres lub kiv cua ntawm lub pob zeb du, calibrate lub dav hlau nrog gaskets ntawm cov kiv cua thiab lub hauv paus, ces sau cov grout. Nyob rau tib lub sijhawm, sau cov grout rau hauv qhov npaj bolts qhov ua ntej, thiab kho cov bolts vertically.

Tighten basal bolts sib npaug, los yog lwm yam yuav ua rau kev mus ncig ntawm lub hauv paus ncej thiab scathe ntawm bears.

Hauv qhov kev sib txuas no, koj yuav zoo dua xav txog kev sib pauv bearings expediently thiab tsis txhob txo tus kiv cua sim koj qhov zoo tshaj plaws.

Teeb qhov rais lossis qhov rooj rau kev tshuaj xyuas thiab sib pauv cov kabmob.

Yog tias lub kiv cua tau nruab nrog lub caij nplooj ntoos hlav damper, qhov sib npaug qhov siab yuav tsum tau mus txog hauv Daim Ntawv 1: chav tsev: mm

| Chassis Ntev L | ≤2000 | >2000~3000 | >3000~4000 | >4000 | Sau ntawv |

| Ua siab ntev | 3~5 | 4~6 | 5~7 | 6~8 | Balanced Tolerance |

| Lus Cim: Qhov siab ntawm loaded damper yuav tsum zoo ib yam, thiab tsuas yog loaded nrog ntsug quab yuam, tsis muaj tangential los yog torsion quab yuam. | |||||

2.Installation ntawm cov kabmob box

Koj yuav tsum pom tias lub zog axile tsis muaj kev cuam tshuam rau cov bearings thaum nruj tag nrho cov bolts.

Kev siv cov kabmob hauv tsev

Tighten lub bolts qhov twg ntawm lub tsev bearing raws li kev kos duab 8. Tom qab zawm cov bolts hauv qab, rau lub dav hlau midsplit bearing lub tsev, ua ntej zawm lub free side bolts maj mam, feem ntau, peb coj lub motor sab li fetterless sab, rau cov kiv cua kub thiab kiv cua uas tau tsav los ntawm hom E kuj xaiv sab tsis muaj lub cev muaj zog, ces zawm lub bolts sab ntawm fetterless.

Yuav tsum xav txog kev nthuav dav ntawm cov kiv cua kub.

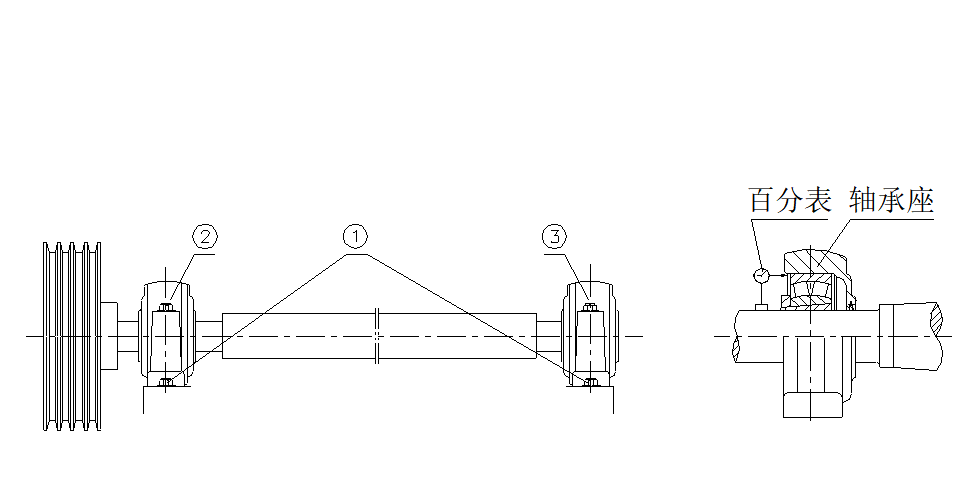

Cov txheej txheem ntawm emendation ntawm ncej thiab bearings

Daim duab 8 Daim duab 9

Muab tso rau hauv lub lateral cover, thauj ib tug centesimal saib, coj tus taw tes txiav txim nrog periphery ntawm bearings (yog hais tias nws yog tsis yooj yim sua, coj mus rau sab ntawm bearing tsev). Tig lub ncej maj mam, thiab tom qab ntawd nyeem thiab kos tus nqi loj tshaj plaws thiab qhov tsawg tshaj plaws. Tom qab ntawd peb tau txais tus nqi wiggle T, tus nqi no sib npaug thiab nqis tus nqi rho tawm sab xis thiab sab laug. Yog tias qhov kev ncua deb ntawm qhov ntsuas taw tes rau axes yog R, T faib R sib npaug gradient tus nqi.

Qhov tso cai gradient tus nqi rau ob-kab tus kheej-aligning rau cov menyuam bearings thiab pob bearings txawv nyob ntawm seb qhov loj thiab qhov chaw thau khoom. Nyob rau hauv ib txwm loading mob nws yuav tsum nyob nruab nrab ntawm 1.5o~ 2.5 Nwso. Txawm hais tias qhov teeb tsa tus nqi tuaj yeem ncav cuag, nyob ntawm tus qauv tsim qauv thiab sealing qauv.

Kev siv cov kabmob

Txawm tias cov bearings muaj 2°adjustable ntau yam nrog nws tsis siv neeg kev ua tau zoo, koj yuav zoo dua them sai sai rau installation vim lub bracket ntawm no unit yog heev yooj yim:

Unit ntawm bearing nrog nres txav bolts

Ua ib qho bore thiab orientation tom qab kho qhov kev ncua deb ntawm bearings. Lub qhov taw qhia txoj hauj lwm qhov yuav tsum zoo ib yam nrog kev thov. Koj yuav tsum tau xyuam xim pib thiab hloov cov bolts txhua hnub. Txwv tsis pub coj kev sib tw kis las ntawm sab hauv npog thiab bearings. Saib daim duab 10.

Nyob rau hauv txoj cai wedge, lub hom phiaj ntawm kev kho cov bearings ntawm lub ncej yog zoo. Muab lub nplhaib eccentricity rau ntawm qhov ntev uas muaj eccentricity, ces nruj nws. Nyob rau tib lub sijhawm, pom lub bolt. Saib daim duab 11.

Kos 10 Drawing 11a Kos 11b

Nws siv nruj txoj hauj lwm bushing kom ncav cuag nruj haum ntawm cov kabmob, hav txwv yeem thiab qag. Thaum lub sij hawm installation, thov xyuam xim hais tias thaum lub bearing yog nias mus rau lub conical Bush thiab round ntsia hlau ceev ceev, radial txav yuav tshwm sim thiab lub radial puab qhov chaw ntawm bearing yuav raug txo (kos duab 11b). Peb pom zoo kom koj cia cov kws paub txog kev siv qhov sib txuas kom nruj cov txiv ntoo no.

3.Notarize cov kev taw qhia ntawm lub cev muaj zog

Notarize tsis muaj qhov txawv txav thaum nruab lub cev muaj zog.

Notarize cov kev taw qhia ntawm lub cev muaj zog yog qhov tseeb ua ntej dai rau ntawm V-siv los yog nruab cov ncej sib koom ua ke.

≤0.15 ~ 0.20mm Radial yuam kev b≤0.15 ~ 0.20mm

4.V-siv thiab rubey

Txheeb xyuas V-siv thiab rubey ua ntej kiv cua pib, kho qhov chaw nruab nrab ntawm ob lub pulleys thiab kho cov kab mob V-siv.

Saib tshooj thib rau txog kev saib xyuas thiab kev kuaj xyuas lub log siv thiab V-siv.

5.shaft sib koom ua ke emendation

Thaum txhim kho cov kiv cua uas tau tsav los ntawm kev sib koom ua ke, qhov emendation nrog cov ncej sib koom ua ke. Thaum xub thawj demount lub bolts, muab tso rau hauv tus pin, tig lub flange tais, xyuas cov windage tib lub sij hawm. Nyob rau hauv ntau, feem ntau, windage ntau yam tau pom nyob rau hauv daim duab 12.

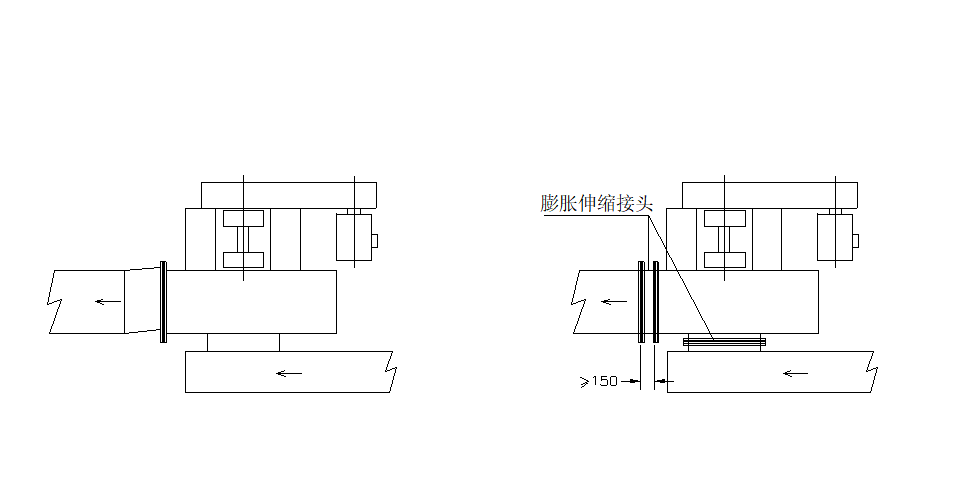

6. Kev sib koom ua ke ntawm cov kav dej

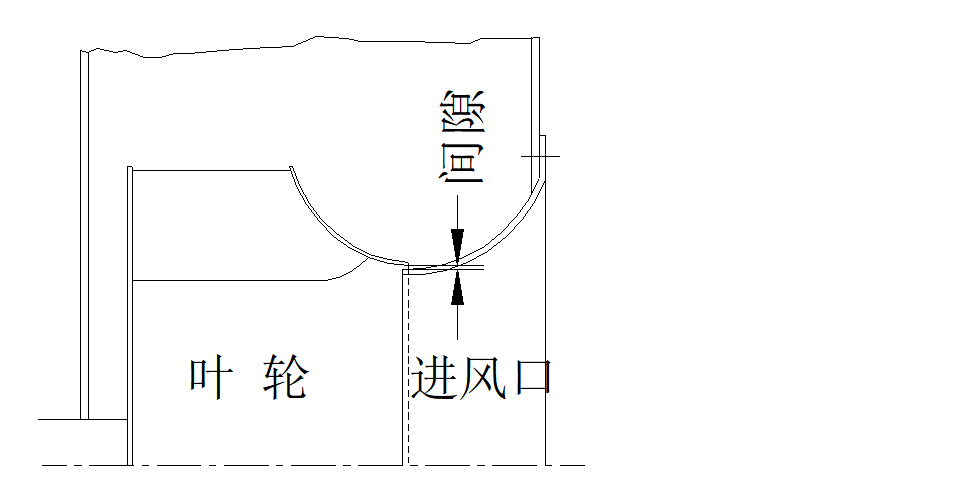

Cov kiv cua tau koom nrog cov yeeb nkab hloov tau yooj yim, ceev cov bolts sib npaug, tau txais qhov chaw zoo ib yam, txwv tsis pub, anamorphic casing yuav ua rau muaj kev cuam tshuam ntawm inlet thiab impeller.

Xyuas cov kiv cua sab hauv ua ntej koom, yuav tsum ntxuav tawm lub eyewinker.

Teem ib qho kev nyab xeeb nrog kev siv txaus ntawm qhov nkag thaum lub kiv cua yuav tsis txuas nrog cov yeeb nkab.

Thaum kawg ntawm kev teeb tsa, xyuas qhov kev tshem tawm ntawm impeller thiab inlet, xyuas kom meej tias qhov kev tshem tawm yog sib luag thiab zoo ib yam. Saib daim duab 15

7.Kev txhim kho cov cua kub cua tshuab

Txhawm rau kom tsis txhob muaj qhov tshwm sim ntawm kev nthuav dav nrog cua sov rau lub kiv cua.

1.Joint ntawm inlet thiab qhov hluav taws xob

Yuav tsum tau siv lub inflatable khi-nyob rau hauv, lub tshav kub kev ntxhov siab yog tsis them nrog kiv cua. Rau armor phaj qauv yeeb nkab, qhov kub hloov pauv 100 ℃ txhua 1000 hli, qhov ntim ntawm distortion yog li 1.3 hli. Saib daim duab 13.

Hmoov tsis zoo

Daim duab 13

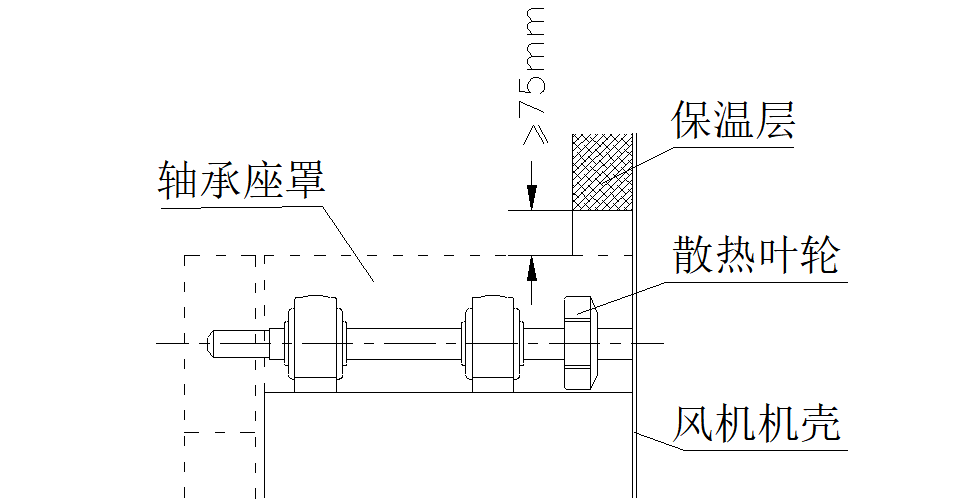

2.Qhov cua txias ntawm cov kabmob

Txhawm rau txo qhov tshwm sim ntawm qhov kub nruab nrab, nruab ib lub kiv cua tawm (rau cov roj kub tsawg dua 250 ℃). Thiab tsis txhob ntsa rau sab nraum lub kiv cua. Saib daim duab 14.

Daim duab 14

Daim duab 15

5. Kev ua haujlwm

Cov txheej txheem raws li nram no:

Tshawb xyuas

Tighten txhua bolts thiab txiv ntseej sib npaug, los yog lwm yam tshwm sim suab nrov, libration, cua divulgence thiab puas ntawm bearings thiab ncej.

Muab tso rau ntawm qhov cub

Cov bearings tau muab cov roj nplua nyeem tsim nyog, yog tias koj xav tau ntxiv, yuav tsum tau lees paub qhov zoo ntawm cov roj nplua nyeem.

Muab tso rau ntawm qhov cub raws li kev taw qhia.

Thov saib tshooj thib rau rau kev ntxiv cov roj nplua nyeem.

Jigger

Thov xyuam xim ua raws li thaum tig lub impeller:

mloog lub suab

Yog hais tias lub suab hnov txawv txawv, thov ceeb toom.

lwm yam

Lub stretch ntawm V-siv.

Qhov kev xav yog hnyav dhau ntawm jigger.

Cua pub noj system

Tag nrho cov khoom ua tau raws li qhov xav tau.

Eyewinker nyob ze ntawm lub qhov hluav taws xob lossis hauv kiv cua.

Thaum khiav, yog tias muaj kev ruaj ntseg nyob ib ncig ntawm lub qhov hluav taws xob.

Hluav taws xob fittings

Xyuas kom tsis muaj qhov qhib Circuit Court hauv qhov system.

Mus hla qhov kev sib txuas hauv lub thawv sib txuas.

Pib

Pib tom qab ntawv pov hwm qhov kev txiav txim ntawm kiv cua system, hluav taws xob system thiab lwm yam tshuab. Tig rau ntawm qhov hloov, tua tom qab 3 ~ 6 vib nas this, xyuas kom qhov tig, libration thiab suab yog qhov tseeb.

Hauv qhov kev khiav tam sim no, tshuaj xyuas thiab kho raws li cov lus qhia pem hauv ntej yog tias muaj qhov txawv txav, ces pib dua.

Cov hluav taws xob tam sim no muaj 5 ~ 7 zaug rau kev ntsuas hluav taws xob tam sim no ntawm kiv cua ad lub cev muaj zog thaum pib, ces maj mam debase. Yog hais tias cov hluav taws xob tam sim no yuav debase qeeb heev, koj yuav tsum xyuas cov hluav taws xob.

Notarized khiav

Yog tias tsim nyog, qhib lossis kaw lub qhov rooj hloov maj mam tom qab koj tau txais tus nqi ntawm lub amperometer.

Kos qhov hluav taws xob tam sim no thiab siab

Xyuas cov libration, kub thiab suab ntawm bearings.

Thaum lub sij hawm ib lub lim tiam los ntawm tus kiv cua pib, thov xyuam xim rau cov hauv qab no:

Kev sib txhuam ntawm rotors

Nruab nrab ntawm impeller thiab inlet

Nruab nrab ntawm impeller thiab casing

Nruab nrab ntawm ncej thiab casing

Nruab nrab ntawm V-siv thiab siv lub hau npog

Fettle ntawm V-siv

Txheeb xyuas qhov sib npaug ntawm V-siv

Txoj siv tawv V-siv

Abrasion ntawm V-siv

Swing ntawm ncej sib koom

Deflection ntawm foliose regulating valve.

Lwm yam

Inhalation ntawm eyewinkers

Libration ntawm tus kiv cua

Tom qab kev sim khiav, kaw lub kaw lus kom kho V-siv siv.

Xyuas cov bearings nrog nws cov lubricator withal.

Rau cov kiv cua kub uas tsis muaj jigger, kaw lub kaw lus thaum qhov kub ntawm sab hauv txo mus rau 100 ℃.

Qhov kev ua tau zoo tsis tuaj yeem hloov pauv los ntawm kev nce kev sib hloov ceev. Txwv tsis pub coj kev huam yuaj.

Kev tu thiab kev tswj xyuas

Kev tshuaj xyuas tau faib ua ntu ntu thiab kuaj xyuas txhua hnub. Koj yuav zoo dua them rau ib feem ntawm kev sib kis hauv kev txheeb xyuas txhua hnub.

Yog hais tias tus kiv cua khiav placidly thaum khiav-hauv, eriodic kos raws li daim ntawv 2 rau 2 ~ 3 lub lis piam nrug.

| kos ib feem | yam | cov ntsiab lus |

| meter | amperer ntsuas voltmeter ntsuas lub tachometer | Seb lub 'meter' muaj txawv txav? txawm hais tias lub zeem muag muaj qhov txawv txav? |

| casing

| co | Seb cov bolts ua tau yooj yim? Txawm hais tias kev sib koom ua ke nrog nto thiab thav duab tau tawg? |

| tshuab tshuab | Puas yog lub foob puas raug puas tsuaj? | |

| casing | co | Seb cov bolts ua tau yooj yim? Txawm hais tias kev sib koom ua ke nrog nto thiab thav duab tau tawg? |

| tshuab tshuab | Puas yog lub foob puas raug puas tsuaj? | |

| impeller | Rub nrog casing | Seb qhov clearance hauv inlet yog vaj huam sib luag? Seb lub clearance nrog casing yog vaj huam sib luag? (axial kiv cua) Puas yog lub cev muaj zog ua kom plumbed nrog casing? |

| impeller | co | Seb cov hmoov av puas tau zoo?unbalance Seb cov bolts ntawm hub yuav hloov tau? |

| distortion ntawm impeller | Cauterization abrasion thiab distortion ntshai | |

| distortion ntawm impeller | Puas yog ib feem ntawm kev teeb tsa bearings thiab cov kabmob npog puas puas lawm? | |

| bearing bearing tsev | co, cua sov, suab nrov

| Seb cov bolts thiab gaskets hloov tau? Txawm hais tias cov bearings puas lawm? Puas yog cov roj xau? Yog tias lub foob yog dhau lawm? Puas yog lub lubrication ntau dhau thiab tsis huv? Xyuas lub suab nrov nrog stethoscope. Puas yog qhov kub siab dua kov nrog tes thiab ntsuas kub? |

| puag | co | Seb cov bolts hauv qab yuav hloov tau? Txawm hais tias lub hauv paus zoo? |

| rubey V- siv ncej puab lwm yam | qab, heat | Seb cov siv yog skid thiab attrite? Seb lub pulleys yog balanced? Puas yog cov yuam sij hloov pauv tau? Seb cov log siv yog attrite? Txoj siv tawv tsis txaus. Qhov ntev ntawm txhua txoj siv tawv tsis zoo ib yam. Seb lub viav vias ntawm ncej sib koom overrun lub kam rau ua? Seb cov bolts ruaj yuav hloov tau?

|

Daim ntawv 3 yuav qhia koj kom paub qhov ua yuam kev yooj yim.

Daim Ntawv 3 Teeb meem Shooting

| txhaum | vim li cas | Kev ntsuas |

| Volume tsawg dhau | static siab tsim me me heev cov kav dej pa tawm thiab tiv taus yog loj heev adjustive qhov rooj qhib me me heev txoj kev tig yog yuam kev qhov ceev txo vim txoj hlua khi | transvaluation ntawm tus tsim kho tom qab kuaj xyuas kho muab txoj cai rau lub sijhawm kho txoj hlua khi |

| overloading ntawm lub cev muaj zog | txoj siv tawv nruj heev yuam kev ntawm lub cev muaj zog xaiv static siab tsim loj heev kho qhov rooj kho qhov phem ua txhaum ntawm lub cev muaj zog | kho txoj hlua khi hloov txo qhov kev sib hloov ceev kho dua kho lossis hloov |

| suab tshwj xeeb | interfused rubbish: tawg los yog caws pliav abrasion ntawm ncej kev sib txhuam ntawm impeller locknut ntawm bearings ua flexible ncej co phem pip system kiv cua hom yog cuav cov airflow ntws gaspingly kev sib txuas ntawm cov kav dej tsis zoo | hloov hloov hloov ceev cov bolts zawm cov bolts dua nrhiav qhov laj thawj thiab kho rebuilt lub system los yog xaiv kiv cua dua kho dua |

| suab tshwj xeeb | interfused eyewinkers huab cua ntim loj heev | tshem tawm rebuilt cov yeeb nkab sysytem |

| kub hoik | bearing kub nrog faults phem ntawm installation impeller tsis zoo ntawm kev sib npaug lubrication ntau dhau tsis muaj lubrication thiab hom lubrication yog cuav lub cev muaj zog tshaj loading, phem ntawm kev sib cais kev sib txhuam hauv qhov chaw kaw | kho qhov tawg lossis hloov cov kabmob kho qhov chaw thiab ceev cov bolts ruaj kho qhov sib npaug ntawm impeller so tawm cov spith muab lipin, pauv tshiab lubrication kho cov load, kho kev sib cais kho lossis nruab dua |

| kev cia siab | base siv tsis txaus kev phem ntawm kev tsim cov bolts hauv qab yuav hloov tau imbalance ntawm impeller kev puas tsuaj ntawm cov bearings abrasion ntawm ncej skid siv cuam tshuam los ntawm sab nraud libration lub viav vias ntawm ncej sib koom overrun lub kam rau ua hom kiv cua yog cuav | txhawb nqa, txhim kho

nruj ntxuav lub impeller, kho qhov nyiaj tshuav pauv pauv kho cov elasticity siv lub shakeproof gasket emendate dua xaiv dua |

Lus Cim: Cov suab no yuav tsum kwv yees los ntawm cov kws tshaj lij muaj kev paub dhau los.

Feem ntau, qhov tsis zoo ntawm cov kiv cua yog lub suab nrov, libration thiab kub kub, yog li ntawd, kev kuaj xyuas txhua hnub yog qhov tseem ceeb.

Libration

Nrog rau cov kab nruab nrab ntawm lub cev muaj zog thiab cov kabmob hauv tsev, txiav txim siab thiab kos tus nqi libration ntawm X, Y, Z kev taw qhia raws li tus qauv JB / T8689-1998.

Yog tias qhov tshwm sim txawv ntawm tus qauv, rov kho qhov tsim nyog.

Peb tsis cia siab tias tus kiv cua khiav qis dua tus qauv, txawm tias tus kiv cua tsis tau lees paub.

Suab

Yog tias tus kiv cua muaj lub suab tshwj xeeb, xyuas kom muaj qhov tshwm sim hauv lub sijhawm raws li hauv qab no: kev sib tsoo ntawm txoj siv sia, cov pob qij txha hloov tau yooj yim, eyewinker, bearings, lub cev muaj zog. Tshwj xeeb tshaj yog xyuas cov bearings.

Thov xyuam xim rau qhov kub ntawm bearings lub tsev thiab casing. Yog tias koj hais rau 3 ~ 4 vib nas this thaum kov qhov chaw, ntawm no thiab tam sim no qhov kub yog 60 ℃.

Lub cev muaj zog khiav qhov kub ntawm qhov sib txawv vim yog qib kev cais tawm. Qhov ntsuas kub tsawg ntawm winding: qib B yog 80 ℃, qib F yog 100 ℃.

Cov log siv nyob rau sab siab ntawm qhov kub thiab txias yuav ua rau muaj kev cuam tshuam ntawm txoj siv sia thaum lub kiv cua nres. Koj yuav tsum tau kho qhov mob.

Kev tu thiab xyuas cov kabmob

Thov xa mus rau phau ntawv style txog kev ua haujlwm ntawm cov kabmob.

Thov xa mus rau qhov no thiab cov chaw tsim khoom tshwj xeeb txog kev teeb tsa thiab kev tshem tawm.

Ntuj lub neej ntawm bearing

Raws li cov kabmob load, cov qauv hauv tsev thiab txawv teb chaws, lub neej ntawm cov kabmob yog 20000 ~ 30000 xuab moos feem ntau ntawm cov rooj plaub tshwj xeeb.

Trademark, ntxiv lub sij hawm, kom muaj nuj nqis ntawm cov roj

Yog tias qhov xwm txheej zoo ib yam nrog kev tiv thaiv kev kub ntxhov, saib daim ntawv 4.Xav txog cov cim lag luam rau kev sib hloov ceev thiab kub tshwj xeeb.

| lub

cov ntsiab lus | domestic bearing | imported bearing | ||||

| lubricating | lubricating | lubricating | lubricating | |||

| yam ntxwv | feem ntau | feem ntau | kub kub | feem ntau | feem ntau | kub kub |

| txheem cim | GB443-89 | GB7324-94 | plhaub gadus s2 v100 2 | GB443-89 | plhaub gadus s2 v100 2 | plhaub |

| code | L-AN46 | 2# | R3 | L-AN46 | R2 | R3 |

| npe | cav roj | Li fat | Li fat | cav roj | Li fat | Li fat |

ntxiv lub sijhawm

Nyob rau hauv ntau, ntxiv raws li daim ntawv 5. Yog hais tias nyob rau hauv lub execrable qhov teeb meem los yog lub system khiav tsis tu ncua nyob rau hauv 24 teev los yog khiav nyob rau hauv plua plav thiab aquosity, lub ncua ncua sij hawm yog ib nrab ntawm daim ntawv 5, kuj deploy ib daim ntaub thaiv npog rau cov bearings.

Infuse lub lubrication maj mam thaum lub kiv cua khiav qis qis lossis jigger nrog tes.

Qhov ntau ntawm append lubrication yog ib feem peb mus rau ib nrab ntawm cov kabmob lossis cov kabmob hauv tsev cubage. Nimiety yog qhov tsis zoo.

daim ntawv 5 lube ntxiv lub sijhawm rau cov kabmob thiab cov kabmob tsev

| khiav kub ntawm bearing (℃) | r / min tig ceev | ||

| ≤1500 tsawg dua 1500 | >1500-3000 tsawg dua 3000 | >3000 tshaj 3000 | |

| ≤ 60 | 4 hli | 3 hli | 2 hli |

| >60 ≤ 70 | 2 hli | 1.5 hli | 1 hli |

| >70 | Qhov kub nce ib 10 ℃, ib nrab lub sij hawm ntxiv (tso cai nce ≤ 40 ℃) | ||

qhib lub thawv bearing los pauv lub roj teeb

Txawm li cas los xij, qhib lub hau npog npog los xyuas ib zaug txhua xyoo tsawg kawg. (Nrog bearings

Puas muaj qhov caws pliav thiab tawg hauv cov kabmob?

Puas yog cov kabmob brim khi nrog cov kabmob zoo? Puas yog qhov pub dawb txav ib txwm?

Lube ntxiv ntawm lub thawv bearing raws li cov roj qib kab qhov rais (saib NOTE mark

Nyob rau hauv nruab nrab ntawm ncej thiab bearing tsev, tag nrho cov bolts thiab gaskets yog nruj.

Infuse lub lubrication tshiab tom qab ntxuav cov bearings.

khiav kub

Qhov kub txog 40 ℃ ~ 70 ℃ ntawm cov kabmob nto yog ntuj, txwv tsis pub, thaum qhov kub siab tshaj 70 ℃, yuav tsum kuaj xyuas lub sijhawm.

Kev tu thiab xyuas ntawm cov ncej txuas

Tswj lub viav vias windage hauv kev thov nruj me ntsis

Hloov tus pin hnav hauv lub sijhawm.

Kev tu thiab xyuas ntawm lub pulley l thiab V-siv

V- siv

Qhov yuam kev yuav tsum nyob rau hauv qhov tso cai khi thaum lub log muaj qee qhov qhib.

Kev ua yuam kev loj loj cuam tshuam rau kev nkees, libration thiab lub neej ntuj tsim.

Loosen lub bolts nyob rau hauv lub hauv paus ntawm lub cev muaj zog, nruab cov hlua khi tom qab koj tau txais qhov chaw nqaim, yog tias koj muab khoom plig rau cov hlua khi rau hauv qhov, cov hlua yuav tawg.

Txhawm rau txo lub neej hauv ntuj thaum cov hlua khi tau stained nrog roj lossis hmoov av, tshwj xeeb yog roj.

Ob lub axes yuav tsum sib npaug, txwv tsis pub, hnav yuav poob qis.

Thov kho qhov tsis sib xws tsawg dua 1/3 °. (Saib daim duab 17)

Post lub sij hawm: Sep-27-2023